|

The body skin was remove from

the timber frame, this needed the bottom six inches replaced all

the way around from scuttle to the scuttle including the doors,

and re-skin the dickey seat lid and golf compartment door. At

this point we threw away the Yale household night latch on the

golf door and replaced it with the correct lock.

The firewall was replace with

a new hand made one, as the wood scuttle frame was broken at the

joints, the movement of the unsupported firewall had caused

large splits to develop. Heavy non original steel brackets had

been made to support it, these were discarded.

Much of the timber frame was

in poor condition, the scuttle was replaced, as were some of

the rails, one door frame and the dickey seat lid frame. |

|

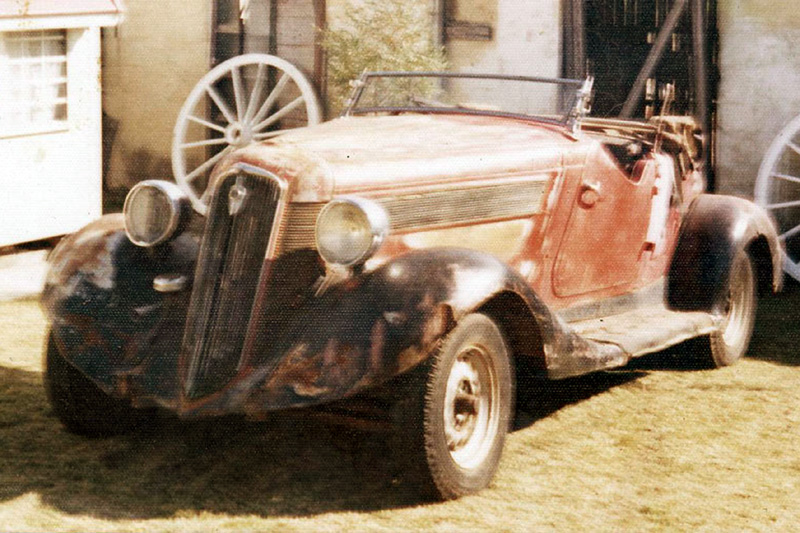

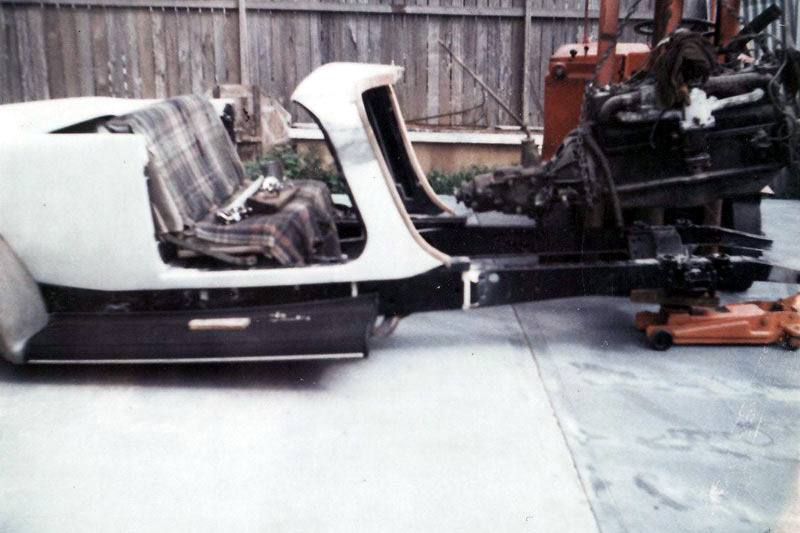

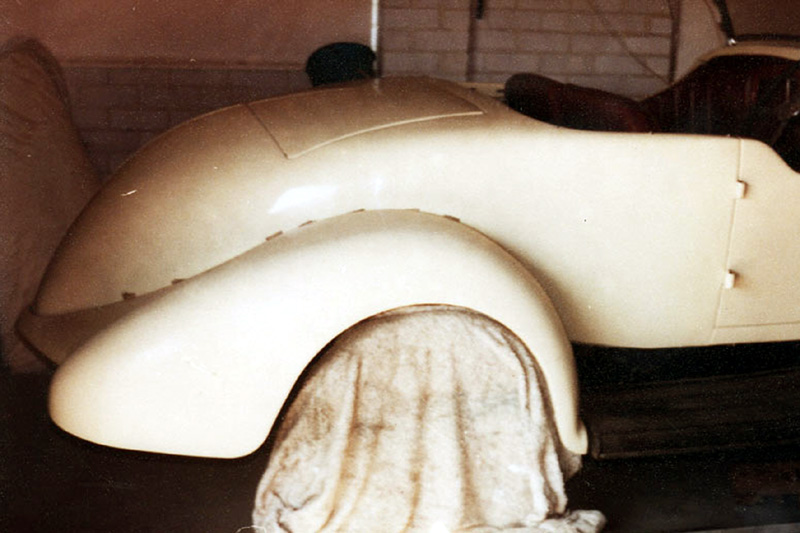

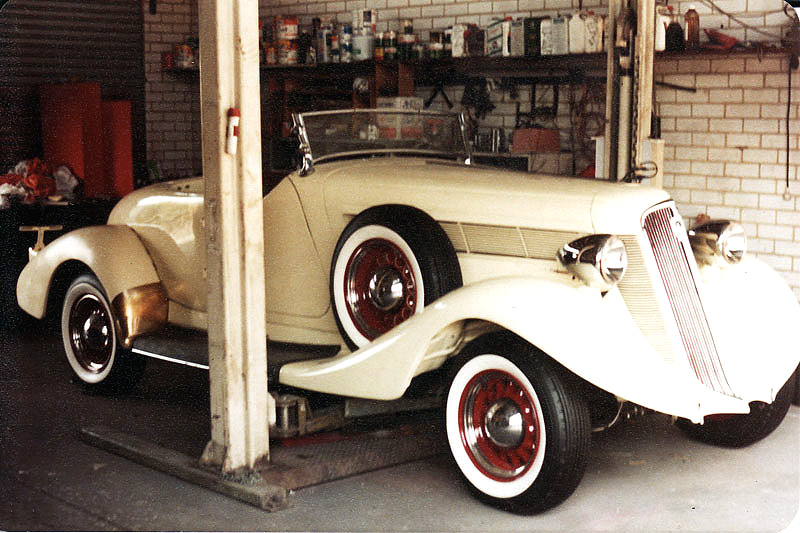

Above and below. This is

the car once I got it home and place the loose pieces on it for

the photo. |

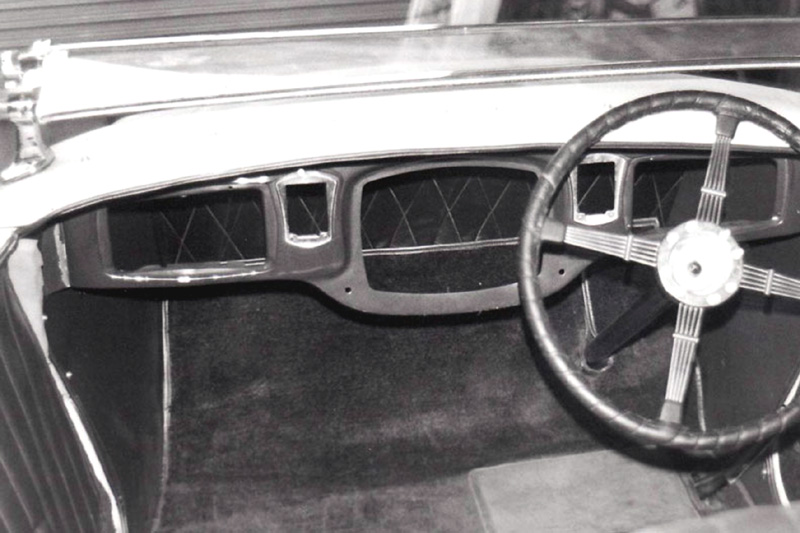

The dash panel before and after.

|

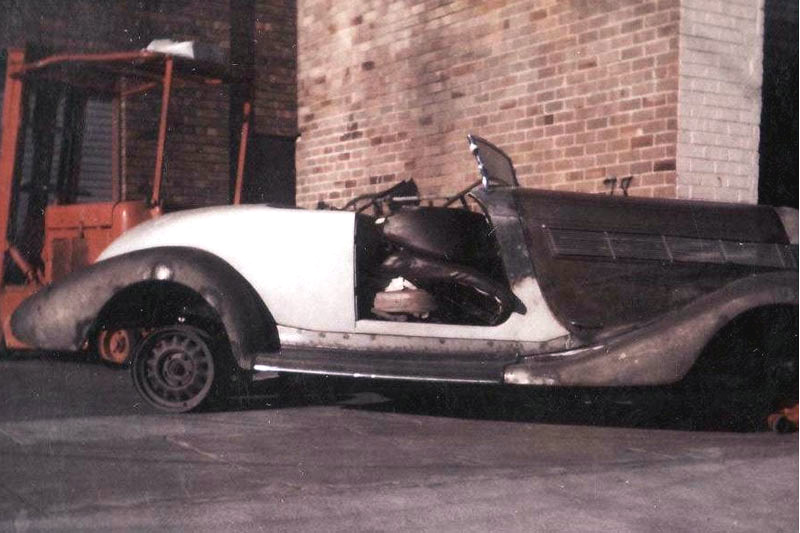

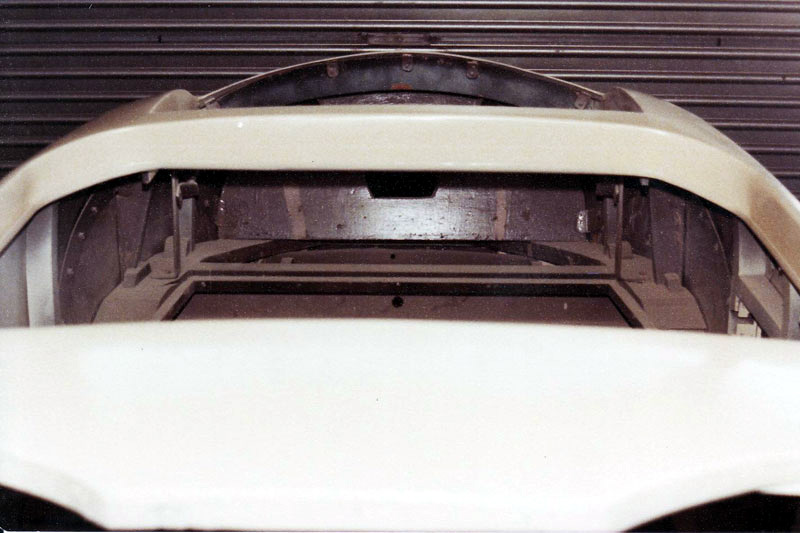

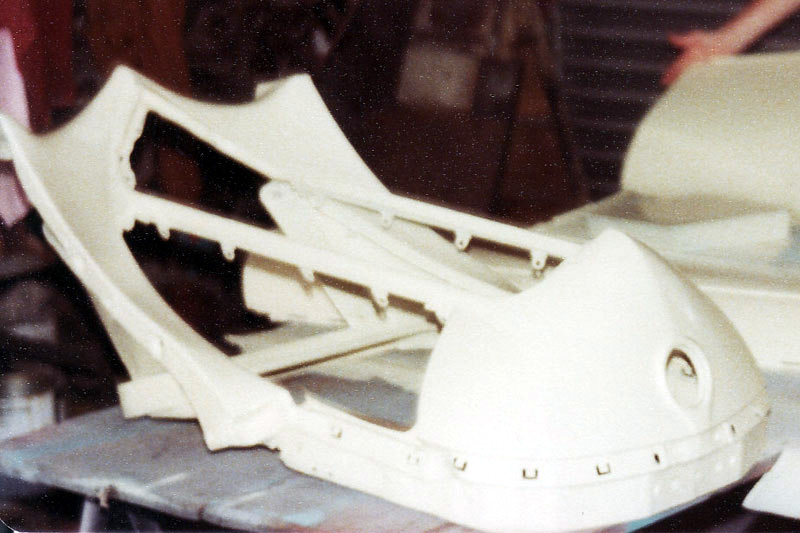

The steel skin removed to replace the rotted wood

and to repair the steel panels

|

|

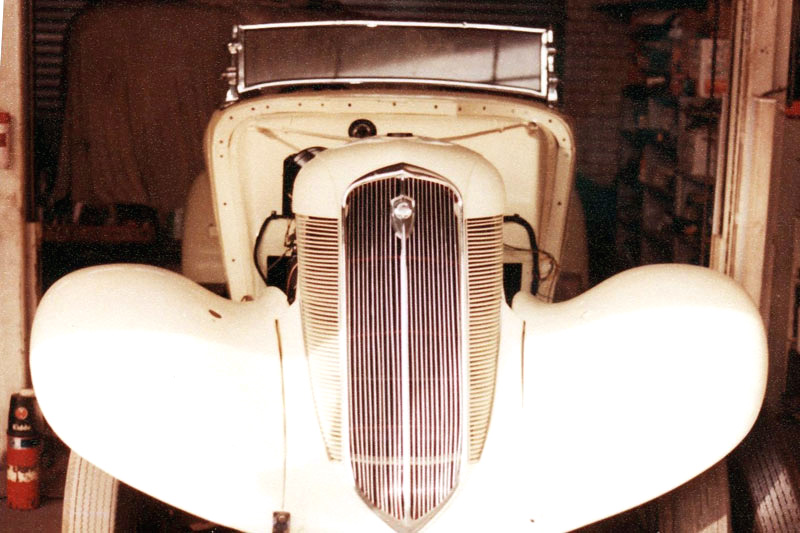

The body

was put back on the chassis. As the front of the car was damaged, I

acquired from Needhams Motors a new front mudguard and a good

secondhand front mudguard, I was lucky enough to get a pair of

brand new old stock running boards, I also was able to get a good

secondhand radiator shell with side grilles, a new centre grille and

new die cast surround. I assembled all these parts plus the repaired

valances on the car to ensure the correct fit. the body then came

off the chassis, I had spent many hours cleaning it by hand with

degreaser, scrapers and hammer and chisel. At this stage I realised

that I was wasting my time, So I removed all the mechanical parts

from the chassis and sent it off to be sandblasted. The chassis was

in remarkably good condition, obviously protected by the build up of

oil and grease. Once back from the sandblasters I coated it with

generous amounts of primer and gloss enamel

I spent many hours stripping the

paint from the panels with paint remover and removing the rust with

rust remover and a wire brush.Next I primed all the panels filled

all the imperfections with spray putty, more primer and gave it

several coats of a 1930s cream acrylic lacquer.The dash panel had

had many of the holes enlarged and extra non original holes added

these all had to be filled and the original holes put back in the

original location. The drivers side glove box lid had to be remade

and the passenger side had a large rectangular no original hole

which was also filled up.

All the wheel rims were damaged, I

was able to acquire modern safety rims that fitted the centres and

had them fitted, They were painted in two pack enamel in maroon to

match the dash panel and fitted with 670x16 Dunlop road speed tyres,

which I painted white walls on, these were later changed for 700x16

Firestone wide white wall tyres, (the original tyre size is 650x16

with 700x16 optional equipment).

It was now time for the body to go

back on the chassis this time to stay. |

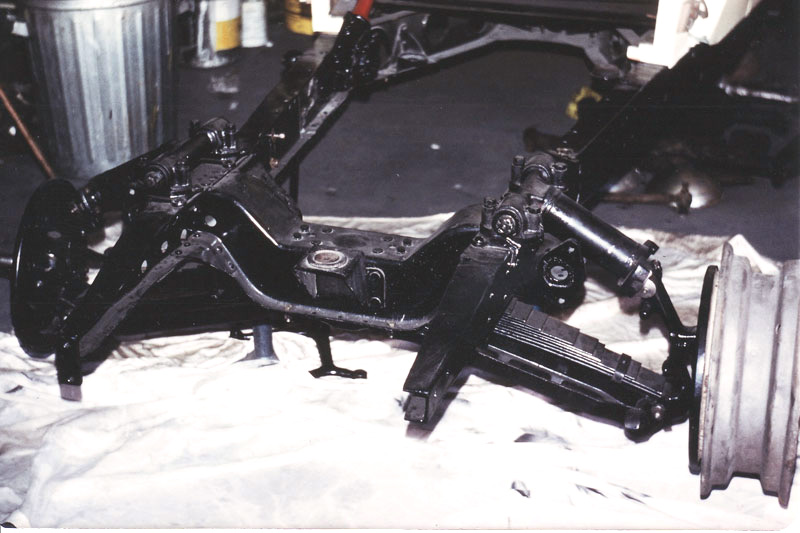

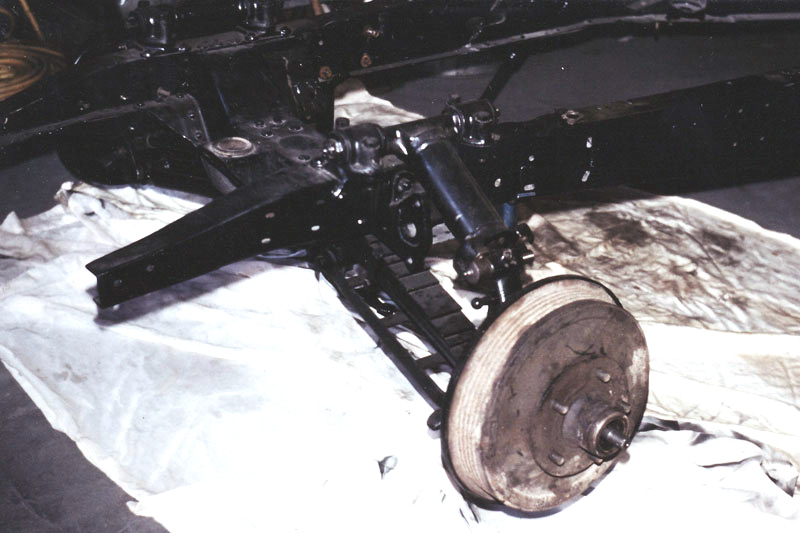

The chassis was sand blasted and given generous

coatings of enamel.

|

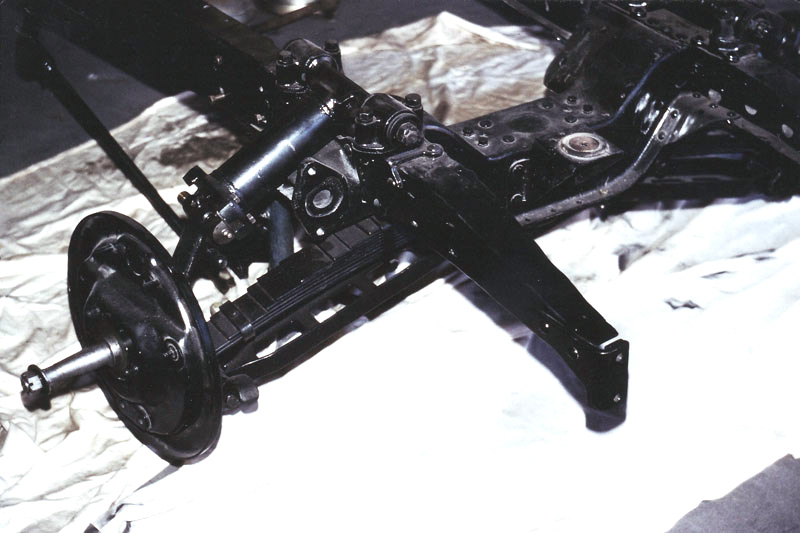

Above and below.

Studebakers independent Planar suspension received a new spring

and pins and bushes. |

|

Above and below .The

steel skin repaired and replaced over the timber frame. |

|

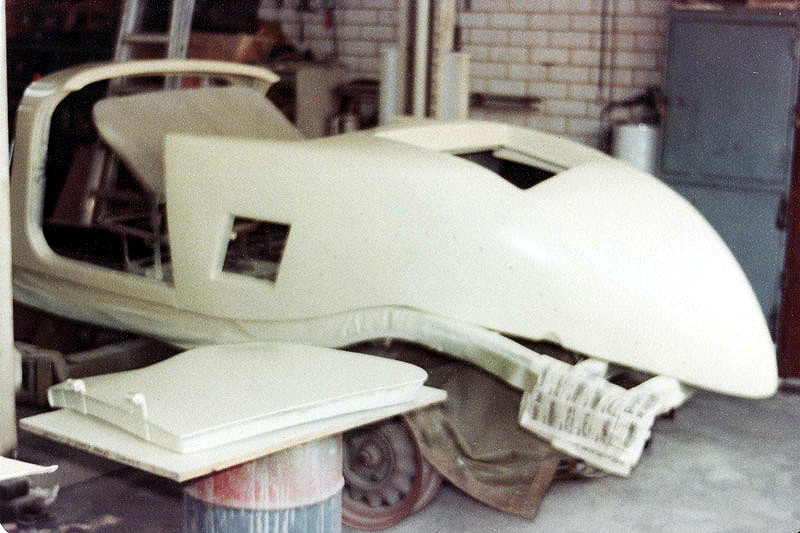

Above and below, The

body painted awaiting cutting back and polishing. |

|

The hood irons and bows. The

problem was I didn't have any! The frame that came with the car

was in poor condition and incomplete and obviously off another

car. The answer was to make a new frame from scratch, I spent

many hours making new hood irons starting with a cardboard

pattern and then graduating to a working hardboard pattern and

eventually the final steel irons. I had them chrome plated, I

assembled the irons with stainless steel rivets. I had the bows

made, I then varnished and assembled them to the irons and then

onto the body.

I fitted the reconditioned rear

axle assembly to the car, (the rear semi elliptic springs were

later removed and reset with new main leaves). I fitted the

newly chromed plated windscreen and stanchions.

The body mounted on the

chassis was towed to the trimmers where it received new maroon

vinyl upholstery, maroon carpet and a white vinyl hood and

tonneau cover in the material usually used on boats, but in the

1980s that was all that was available. In 2007 the hood was

getting a little tatty as was the paint on the car, many

adjustments and minor repairs were made, the hood material was

replaced with an off white canvas and the vinyl maroon

upholstery was replaced with maroon leather. |

|

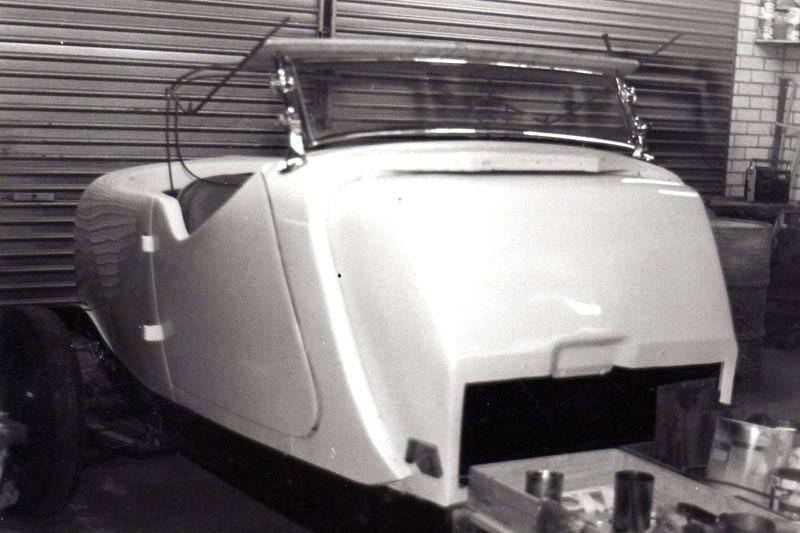

On the way to the motor

trimmers to be upholstered. |

|

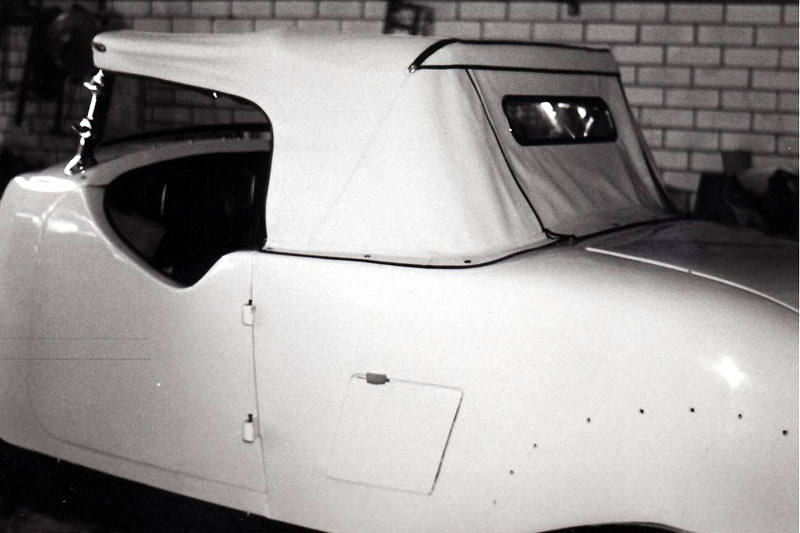

Above and below. Back

from the motor trimmers. |

|

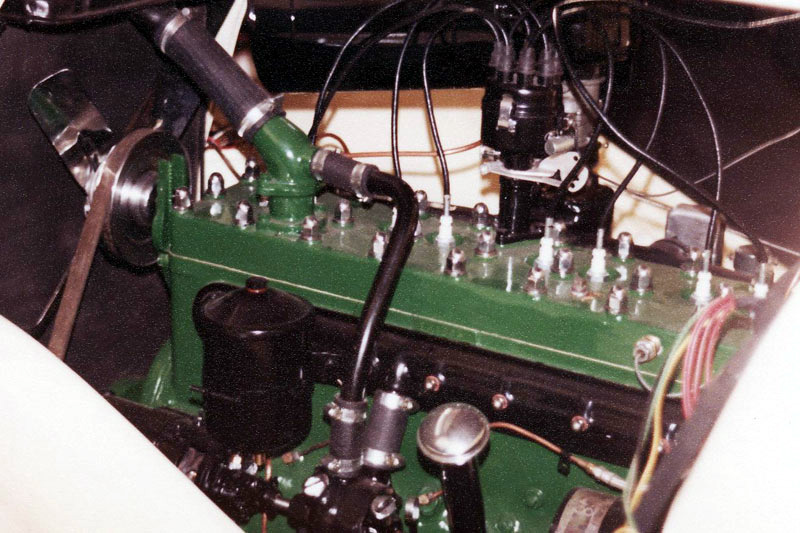

Above and below. The fully

reconditioned engine fitted in the car |

| |

|

Whilst the car was at the motor

trimmers to the engine was sent out, to be machined, this included

boring to 60 thou oversize, (I believe this to be it’s second rebore),

crankshaft grind, new pistons, gudgeon pins, rings, big end, main

and cam shaft bearings, new valves. All moving parts were balanced

including the flywheel. As it turned out the original Studebaker

parts did not need attention as they were already balanced, courtesy

of the Studebaker factory at South bend Indiana in 1935. The oil

pump water pump,12V generator and the starter motor were

reconditioned. Eighty hours was spent assembling the engine

cleaning the oil galleries plasti gauging the bearings, matching the

manifolds and ports and another forty hours preparing and painting

the engine with a heat resistant primer and gloss green enamel.

The body came back from the

trimmers and I started on the steering and front suspension. I was

surprise of the quality of the steering and independent front

suspension. The Ross steering box is the same as used on the J model

Duisenberg! It is the worm and pin type the pin running on a double

row Timken bearing. with tie rods to each wheel, The front

suspension is Studebaker’s Planer type, which consist of a massive

transverse spring, which (I acquire a brand new spring from

Needham’s) and upper and lower control arms, The upper outer knuckle

supports are in needle roller bearings, the inner upper pivots are

very large rubber bushes, the lower inner pivots are rubber bushes

and the lower outer pivots are a threaded pin, I was able to buy all

these parts new. The rear suspension bushes are the split rubber

type the same as used on a modern leaf spring vehicle

The instruments were checked and

repaired where necessary and fitted to the car.

The engine was lifted into the

chassis, fitted new engine mountings, and fitted the accessories,

starter generator, water pump etc, fitted and connected the new 2

inch exhaust, with tandem mufflers. fitted the radiator grilles and

radiator to the shell and fitted the whole assembly to the car and

connected the radiator hoses to the engine.

By now I was getting anxious to

start the engine, I ran a temporary fuel line from a bottle and

connected a battery. A few quick turns of the starter and the engine

burst into life for the first time in eight years. |

|

Above and below. The

final assembly, as panel by panel is fitted. |

|

I made a new wiring harness

with Australian made electrical cable, including provision for

flasher lights, fog, and driving lights.

The mudguards were fitted, the

bonnet top and then the bonnet sides.

Then the headlights and tail

lights were fitted and connected.

The reconditioned clutch,

gearbox, reconditioned diff centre and axles including all new

bearings, tail shaft, new universal joints were fitted

The next six months were spent

fitting the bumper bars, making and connecting linkages and all

those five and ten minute jobs that I can assure you take a lot

longer.

The brakes were totally

overhauled, this included machining the 121/8” composite steel

and cast iron brake drums, lining the brakes with MZ5 woven

linings, lining the master and wheel cylinders with stainless

steel sleeves, making all new rigid brake lines and fitting new

flexible hoses and filling the system with silicon brake fluid.

At last the car was ready to

register.

The restoration took fourteen

years, funny how things take so much longer than you imagine! |

|

The car now almost

complete. |

This is the

car in 2011.

In 2007, after

22 years on the road and traveling all over NSW as far as the Queensland

border, it

receive a new

hood (top) new leather upholstery, new paint, new 700x16 Firestone wide

white wall tyres. |